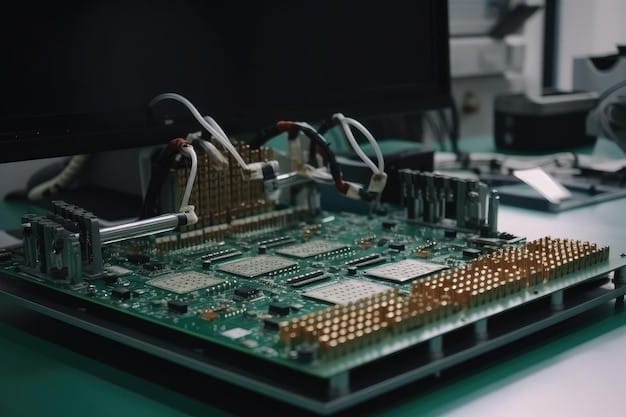

As technology continues to advance at a rapid pace, Arm development boards have emerged as powerful tools for accelerating the development of industrial applications. These boards, also known as single-board computers (SBCs), offer engineers the opportunity to familiarize themselves with Arm microcontrollers and facilitate both hardware and firmware development. However, it is important to understand the limitations of development boards compared to industrial-grade SBCs, and to carefully evaluate their suitability for continuous use in industrial applications.

While Arm development boards and industrial SBCs share similarities in terms of their purpose, there are important distinctions that engineers need to be aware of. Industrial SBCs undergo rigorous quality assurance (QA) testing to ensure their reliability and performance under harsh industrial conditions. These SBCs are designed to operate within wide temperature ranges, typically from -40°C to +85°C, and are equipped with components specifically chosen for their ability to withstand these extreme conditions. They are also subjected to thorough QA testing, including stress tests, to identify and rectify any issues before being released for production.

On the other hand, Arm development boards are primarily designed for evaluation and demonstration purposes. While they may use commercial-grade components, they are typically only tested at room temperature and low humidity. This raises concerns about their reliability and suitability for continuous use in industrial applications. Therefore, engineers must take a proactive approach to assess the suitability of development boards for their specific application requirements.

When considering the use of an Arm development board in an industrial application, it is crucial to assess the manufacturer’s end-of-life (EOL) policy and track record for development boards. This helps reduce the risk of selecting a board that may be discontinued in the future, leaving engineers with no support or replacement options. Additionally, engineers should carefully examine the components used on the board to ensure they are suitable for the target application’s temperature range.

To further mitigate risk, engineers should subject the development board to rigorous testing before approving it for continuous use. This includes stress testing the boards under high temperature conditions for an extended period. Multiple boards should be tested to gauge production consistency, as different production lots may exhibit variations in performance. It is also important to verify the board’s performance under high humidity or vibration conditions, if applicable to the intended application.

Furthermore, engineers should inquire about the manufacturer’s policy on engineering change notices (ECNs). Regularly checking for ECNs helps ensure that any changes made to the board’s components are communicated, allowing engineers to assess the impact on their application. By following these steps, engineers can make informed decisions and select a development board that meets the requirements of their industrial application.

While Arm development boards may not be explicitly certified for continuous industrial use, there are certain boards that have potential for application in industrial settings. Let’s explore two examples of development boards and discuss their suitability for industrial use.

The STMicroelectronics NUCLEO-L4P5ZG is an Arduino-compatible Nucleo board that offers basic development board functionality. It is based on an Arm Cortex-M4 microcontroller and provides access to all the microcontroller’s GPIO pins through header connectors. The board features three user-programmable LEDs, a user pushbutton, and a reset button. It also includes USB On-The-Go (OTG) Full Speed and micro USB connectors for programming and debugging purposes.

One advantage of the NUCLEO-L4P5ZG is its compatibility with other boards in STMicroelectronics’ Nucleo line. This allows for easy sourcing of compatible replacements in case of product discontinuance. The board’s ability to manage I/O, such as sensors, switches, and actuators, makes it suitable for various industrial applications.

The Infineon Technologies KITXMC47RELAXV1TOBO1 Relax Kit is another Arm Cortex-M4-based development board that offers a range of features for possible industrial applications. It provides a full set of Arduino pads without header connectors, allowing for flexible usage. The board includes an RJ45 connector for Ethernet networking, making it suitable for networked applications or basic Industrial IoT (IIoT) nodes. It also features two user pushbuttons, two LEDs under firmware control, and a reset button.

One notable feature of the Relax Kit is its microSD card slot, which facilitates easy firmware or application data changes by simply swapping in a different microSD card. This is particularly useful for applications where frequent changes are required. With its ability to monitor sensors, switches, and control actuators in rugged environments, the Relax Kit demonstrates potential for various industrial use cases.

Arm development boards offer engineers valuable tools for accelerating the development of industrial applications. However, it is essential to understand the differences between development boards and industrial SBCs, and to carefully evaluate the suitability of development boards for continuous use in industrial settings. By following a thorough evaluation process, engineers can mitigate risks and select development boards that meet their application requirements. With examples like the STMicroelectronics NUCLEO-L4P5ZG and the Infineon Technologies Relax Kit, engineers have options to explore and leverage the potential of Arm development boards in industrial applications.

Remember to conduct extensive research and consult additional sources to enhance the depth and accuracy of your article. Use proper markdown formatting, including headings, subheadings, tables, links, blockquotes, images, ordered and unordered lists, and code snippets, to improve readability and organization. Incorporate relevant keywords strategically to optimize the article for search engines.